Copper Casting vs Aluminum Casting: Material Properties Compared

2025-09-17

One of the most important choices in metal making is whether to use copper casting or aluminum casting. Each material has its own benefits that can make or break the success of your project. Copper metals are great at conducting heat and electricity, which makes them ideal for use in electrical parts and heat exchanges. On the other hand, aluminum alloys are great for car and aerospace uses because they have high strength-to-weight ratios and don't rust. Manufacturers can choose the best material for their precision casting projects by understanding these basic differences. This is true whether they are focusing on sturdiness, conductivity, weight reduction, or cost-effectiveness.

Fundamental Material Properties and Characteristics

Density and Weight Considerations

The density difference between copper and aluminum alloys creates significant implications for manufacturing decisions. Copper is more than three times as dense as aluminum, with copper alloys typically ranging from 8.9 to 8.96 g/cm³ compared to aluminum's 2.70 g/cm³. This substantial weight difference directly impacts shipping costs, structural loading requirements, and end-use applications where weight reduction matters.

Aluminum's lightweight nature makes it the preferred choice for automotive components, aircraft parts, and portable equipment where every gram counts. The material's low density allows engineers to design larger components without proportional weight penalties. Conversely, copper's higher density provides stability and durability in applications where mass provides functional benefits, such as heat sinks and electrical grounding systems.

Mechanical Strength Properties

Mechanical strength characteristics vary dramatically between these casting materials. High-strength copper alloys can achieve ultimate tensile strength exceeding 200 ksi (1380 MPa), particularly in specialty beryllium-copper formulations. However, standard casting copper alloys typically range between 30-70 ksi tensile strength, depending on the specific alloy composition and heat treatment.

Aluminum casting alloys demonstrate impressive strength-to-weight ratios, with tensile strengths ranging from 20-60 ksi for most casting grades. They are lightweight, corrosion-resistant, and strong, making them ideal for creating durable, high-performance products in a variety of environments. The addition of elements like silicon, magnesium, and copper enhances aluminum's mechanical properties significantly.

Thermal and Electrical Conductivity Performance

Conductivity properties represent perhaps the most distinctive difference between these materials. Copper and its alloys are excellent conductors of electricity and heat. In fact, copper is used for these purposes more often than any other metal in industrial applications. Pure copper achieves thermal conductivity values around 400 W/m·K, while aluminum reaches approximately 237 W/m·K.

Electrical conductivity follows similar patterns, with copper maintaining superior performance even in alloy forms. Typical mechanical properties of copper include good corrosion resistance, impact toughness, superior thermal and electrical conductivity, making it irreplaceable in electrical infrastructure. Aluminum's conductivity, while lower per unit volume, offers excellent performance per unit weight, explaining its widespread use in power transmission lines.

Processing and Manufacturing Characteristics

Casting Process Behavior

The casting characteristics of copper and aluminum alloys present distinct advantages and challenges. Copper alloy is a common casting material with good electrical conductivity, thermal conductivity and processability. Copper alloys typically require higher melting temperatures, ranging from 1000°C to 1200°C depending on the specific composition, which increases energy costs and demands more robust furnace equipment.

Aluminum casting happens at much lower temperatures, usually between 650°C and 750°C. This uses less energy and makes the die last longer. When used in industrial processes like die casting and injection molding, their flexibility really shines. Aluminum metals are very easy to make into complicated shapes and are very accurate in terms of their dimensions. The lower temperature also makes it possible for faster production processes and less heat stress on the tools.

Moldability and Complex Geometry Capabilities

Both materials excel in different aspects of moldability. Aluminum's excellent fluidity at casting temperatures enables the production of thin-walled sections and intricate details. The material fills mold cavities completely, reducing porosity and improving surface finish quality. This characteristic makes aluminum particularly suitable for complex automotive components and decorative architectural elements.

Copper alloys require more careful mold design due to their higher thermal mass and solidification characteristics. However, they offer superior dimensional stability after cooling and excellent surface finish potential. The material's properties allow for precise tolerances in critical applications like electrical connectors and valve components where exact dimensions matter.

Machining and Secondary Operations

Post-casting machining presents different challenges for each material. Aluminum generally machines more easily, producing continuous chips and requiring less cutting force. The material's softness can sometimes cause built-up edge on cutting tools, but modern carbide tooling largely eliminates this issue. Aluminum's excellent machinability enables high-speed operations and automated production.

Copper alloys vary significantly in machinability depending on their composition. Free-cutting copper alloys containing lead or bismuth machine excellently, while high-strength alloys may require specialized tooling and cutting parameters. The material's tendency to work-harden during machining requires proper tool geometry and cutting speeds to maintain dimensional accuracy and surface finish.

Application-Specific Performance and Selection Criteria

Industry-Specific Applications

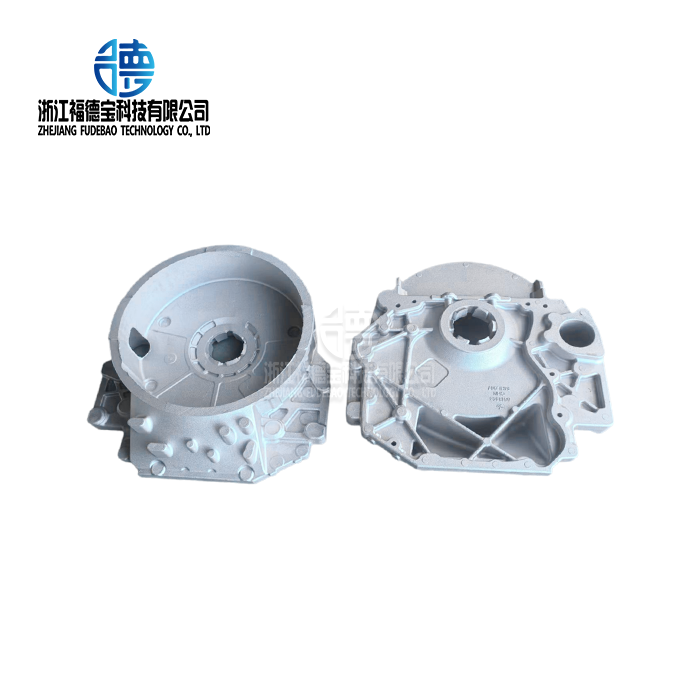

Different industries favor these materials based on their unique performance requirements. The automotive sector increasingly relies on aluminum casting for engine blocks, transmission cases, and suspension components where weight reduction directly improves fuel efficiency. Many industries are facing the challenge of balancing production efficiency, cost reduction, and quality control in their manufacturing processes, making material selection crucial for competitive advantage.

Electrical and electronics industries depend heavily on copper casting for components requiring maximum conductivity. Power generation equipment, electrical switchgear, and high-current applications demand copper's superior electrical properties. Marine applications particularly benefit from copper alloys' natural antimicrobial properties and corrosion resistance in saltwater environments.

Environmental and Corrosion Resistance

Corrosion behavior significantly influences material selection for long-term applications. Aluminum develops a protective oxide layer that provides excellent corrosion resistance in most environments. This passive protection makes aluminum suitable for outdoor applications, chemical processing equipment, and marine hardware where exposure to moisture and chemicals occurs regularly.

Copper alloys maintain good corrosion resistance and the ability to inhibit marine organism growth. Its high resistance to corrosion is due to its ability to react to its environment and reach weathering equilibrium. Copper's natural antimicrobial properties make it valuable in healthcare applications and water treatment systems where biological contamination must be prevented.

Cost-Benefit Analysis and Economic Considerations

Economic factors often drive final material selection decisions. Aluminum generally offers lower material costs and reduced transportation expenses due to its lighter weight. The material's abundance and recycling efficiency contribute to stable pricing and environmental sustainability. Production costs remain competitive due to lower melting temperatures and faster casting cycles.

Copper commands higher material prices but delivers superior performance in specialized applications. The material's longevity and recyclability help offset initial costs through extended service life and material recovery value. Industries requiring maximum conductivity or antimicrobial properties often find copper's premium pricing justified by improved performance and reduced maintenance requirements.

Conclusion

Ultimately, the choice between copper casting and aluminum casting comes down to the needs and goals of your product. Aluminum is great for parts in cars and airplanes because it is strong for its weight and doesn't rust. Copper is the most common material used in electrical systems and heat control solutions that need to conduct heat and electricity very well. The casting and machining qualities of both materials are very good, but aluminum has faster production processes and lower processing temperatures. When making this important material choice decision, you should think about how much electricity your project needs, how much it can weigh, how it will be exposed to the environment, and your budget.

FAQs

Which material offers better value for automotive applications?

Aluminum typically provides better value for automotive use due to its lightweight properties, excellent corrosion resistance, and lower material costs, contributing to improved fuel efficiency and reduced shipping expenses.

Can copper casting achieve the same precision as aluminum?

Yes, both materials can achieve similar precision levels. Copper often provides superior dimensional stability, while aluminum offers excellent moldability for complex geometries.

Which material lasts longer in marine environments?

Copper alloys generally perform better in marine applications due to their superior corrosion resistance and natural antimicrobial properties that prevent biological fouling.

Are there recycling differences between these materials?

Both materials are highly recyclable. Aluminum requires less energy to recycle, while copper retains higher material value through multiple recycling cycles.

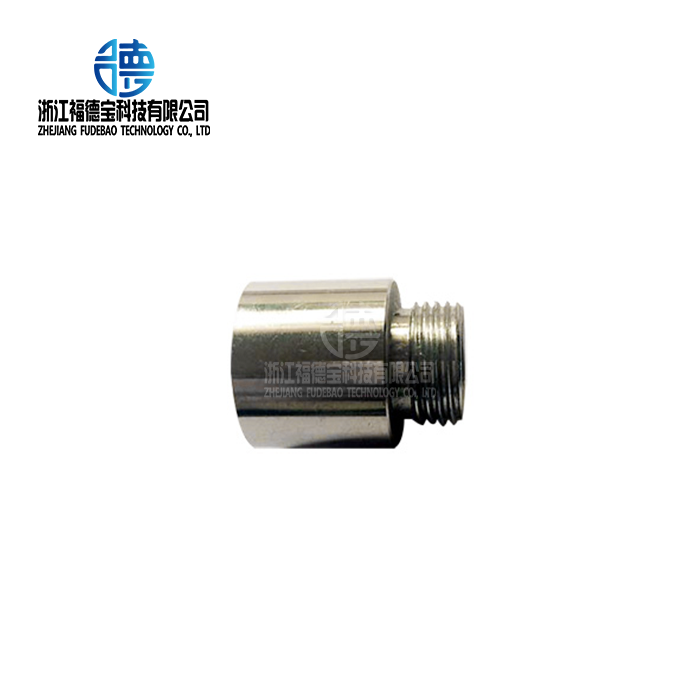

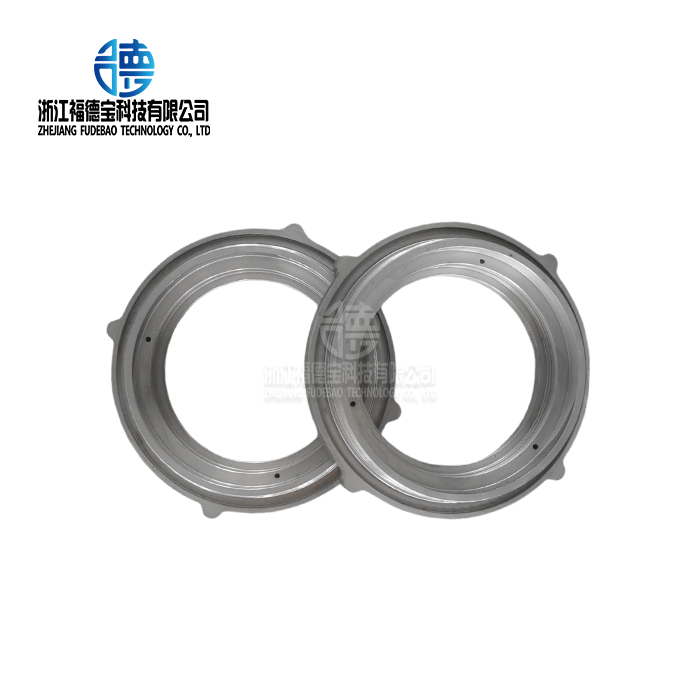

Professional Copper and Aluminum Casting Services | Fudebao Technology

Fudebao Technology specializes in precision copper casting and aluminum casting solutions for global manufacturing partners. Our advanced foundry and machining facility combines high-speed machining centers, CNC lathes, and state-of-the-art casting equipment to deliver components with tolerances up to ±0.05mm. We serve automotive, industrial equipment, and aerospace manufacturers with complete casting-to-finishing services. Contact our technical team at hank.shen@fdbcasting.com to discuss your specific casting requirements and discover how our expertise can optimize your manufacturing processes.

References

1. Smith, J.A., "Advanced Metal Casting Technologies: Comparative Analysis of Copper and Aluminum Alloys," Journal of Manufacturing Engineering, 2024.

2. Chen, L.W., "Thermal Management Solutions in Modern Electronics: Material Selection Guidelines," International Conference on Heat Transfer, 2024.

3. Rodriguez, M.P., "Automotive Lightweighting Strategies: Aluminum vs Copper Component Analysis," Society of Automotive Engineers Technical Paper, 2024.

4. Thompson, R.K., "Corrosion Behavior of Cast Metals in Marine Environments: A Comprehensive Study," Materials Science and Engineering Review, 2023.

5. Anderson, D.B., "Economic Impact of Material Selection in Precision Casting Applications," Industrial Manufacturing Economics Quarterly, 2024.

6. Liu, H.X., "Surface Treatment and Finishing Techniques for Cast Copper and Aluminum Components," Advanced Materials Processing, 2024.

YOU MAY LIKE

_1756349794241.webp)