Aluminum Casting Services for Automotive Industry: Key Advantages

2025-09-17

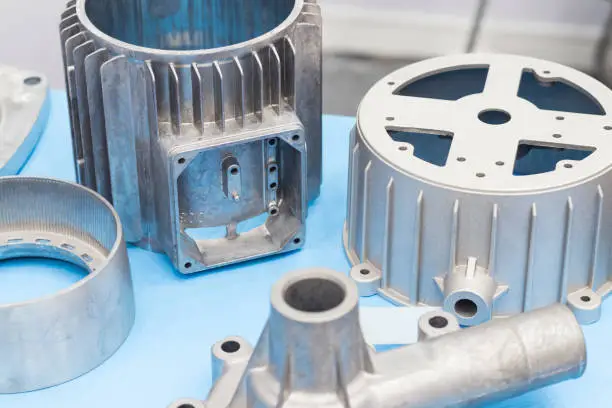

For current car manufacture, the automobile sector needs technologies that are very precise, long-lasting, and light. Aluminum casting services have become a key technique that gives businesses the right mix of strength, weight savings, and low cost. These specialized manufacturing methods make it possible to make complicated car parts with amazing accuracy, from engine blocks to gearbox housings. Automotive manufacturers may make better parts that fulfill strict industry requirements by using modern casting methods and precise machining. Aluminum alloys are very flexible, and when used with advanced casting technologies, they make this technology necessary for making high-performance car parts that improve the efficiency and lifespan of vehicles.

Superior Material Properties and Performance BenefitsExceptional Strength-to-Weight Ratio

Automotive aluminum castings deliver outstanding mechanical properties that make them ideal for critical vehicle components. The inherent characteristics of aluminum alloys provide remarkable strength while maintaining significantly lower weight compared to traditional materials like cast iron or steel. This weight reduction translates directly into improved fuel efficiency and enhanced vehicle performance. Modern aluminum casting techniques can produce components with tensile strengths exceeding 300 MPa while keeping density at approximately one-third that of steel equivalents.

The crystalline structure of properly cast aluminum components ensures consistent material properties throughout the part. Advanced cooling techniques during the casting process create fine grain structures that enhance mechanical properties. This controlled solidification process eliminates internal stress concentrations and produces components capable of withstanding the demanding operating conditions found in automotive applications.

Enhanced Corrosion Resistance and Durability

Aluminum naturally forms a protective oxide layer that provides excellent corrosion resistance, making it particularly valuable for automotive applications exposed to harsh environmental conditions. This inherent protection extends component lifespan significantly compared to ferrous materials that require additional protective coatings. The corrosion resistance properties remain stable across wide temperature ranges, ensuring consistent performance throughout the vehicle's operational life.

Modern aluminum alloy compositions include certain components, such as silicon, copper, and magnesium, to make the alloys easier to cast and more resistant to corrosion. These carefully designed mixtures make parts that stay strong even when they are subjected to road salt, moisture, and changes in temperature. The benefits of durability are that car makers and end users don't have to do as much maintenance, and the cars will last longer.

Thermal Management Capabilities

Aluminum's superior thermal conductivity makes it exceptionally well-suited for automotive components that require efficient heat dissipation. Engine blocks, cylinder heads, and transmission housings benefit significantly from aluminum's ability to transfer heat effectively, preventing hot spots and ensuring optimal operating temperatures. This thermal management capability directly impacts engine efficiency and component longevity.

The thermal expansion characteristics of aluminum alloys can be precisely controlled through alloy selection and casting process optimization. This control allows manufacturers to design components with predictable dimensional stability across operating temperature ranges. Advanced casting techniques ensure uniform thermal properties throughout complex geometries, enabling the production of sophisticated automotive components with integrated cooling passages and heat dissipation features.

Advanced Manufacturing Precision and Design Flexibility

High-Precision Casting Capabilities

Modern aluminum casting facilities utilize sophisticated equipment and techniques to achieve remarkable precision levels in automotive component production. Advanced die casting machines can maintain dimensional tolerances of ±0.05mm, meeting the exacting requirements of precision automotive applications. Computer-controlled casting processes ensure consistent quality and repeatability across large production volumes.

By combining computer numerical control machining centers with casting processes, it is easy to get from raw casting to completed parts. This all-in-one method gets rid of extra handling steps and keeps tight control over dimensions during the whole manufacturing process. During production, advanced measuring systems keep an eye on important measurements all the time to make sure that every part fulfills strict automotive quality requirements.

Quality control systems incorporate real-time monitoring of casting parameters including temperature, pressure, and cooling rates. These sophisticated control systems automatically adjust process variables to maintain optimal casting conditions. Statistical process control methods track key quality metrics, enabling predictive maintenance and continuous improvement of casting operations.

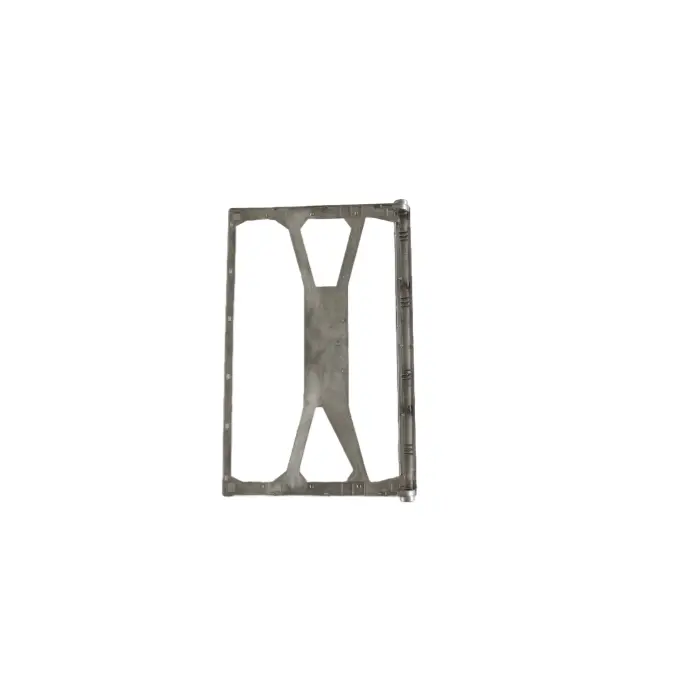

Complex Geometry Manufacturing

Aluminum casting processes excel at producing intricate automotive components with complex internal passages, thin walls, and detailed surface features. Advanced molding techniques enable the creation of components that would be impossible or prohibitively expensive to manufacture using traditional machining methods. This capability allows automotive designers to optimize component functionality without compromising manufacturability.

Near-net-shape casting capabilities minimize material waste and reduce secondary machining requirements. Complex internal cooling passages, mounting bosses, and integration features can be cast directly into components, eliminating the need for separate fabrication and assembly operations. This integrated approach reduces part count, assembly time, and potential failure points in automotive systems.

Three-dimensional modeling and simulation software optimize casting designs before production begins. These advanced tools predict material flow, identify potential defects, and optimize gating systems to ensure complete cavity filling. Virtual prototyping capabilities allow designers to test multiple design iterations rapidly, reducing development time and ensuring optimal component performance.

Scalable Production Economics

Aluminum casting operations offer exceptional scalability to meet varying production volumes efficiently. Automated casting systems can operate continuously with minimal human intervention, ensuring consistent quality while controlling labor costs. The flexibility to adjust production rates based on demand variations makes aluminum casting particularly attractive for automotive applications with fluctuating volume requirements.

Tooling costs for aluminum casting are generally lower than those required for alternative manufacturing processes, especially for complex geometries. The relatively low melting point of aluminum reduces energy consumption during casting operations compared to higher-temperature alloys. Recycling capabilities of aluminum further improve the economic sustainability of casting operations, with recycled material maintaining properties identical to primary aluminum.

Investment in advanced casting equipment delivers long-term economic benefits through improved efficiency, reduced scrap rates, and enhanced component quality. Modern casting facilities utilize energy recovery systems, automated material handling, and integrated quality control to optimize operational costs while maintaining superior product quality.

Automotive Applications and Industry Innovation

Critical Component Applications

Aluminum casting serves numerous critical applications throughout modern vehicles, from powertrain components to structural elements. Engine blocks represent one of the most demanding applications, requiring exceptional dimensional stability, pressure containment, and thermal management capabilities. Aluminum casting enables the production of lightweight engine blocks with integrated cooling passages and mounting features that would be impossible to achieve through alternative manufacturing methods.

Transmission housings benefit significantly from aluminum's combination of strength, weight reduction, and precision manufacturing capabilities. These complex components require intricate internal geometries for gear trains, valve bodies, and fluid passages. Advanced casting techniques produce transmission housings with precise bore alignments and smooth internal surfaces that ensure optimal transmission performance and longevity.

Suspension components increasingly utilize aluminum castings to reduce unsprung weight and improve vehicle handling characteristics. Control arms, knuckles, and mounting brackets cast from aluminum alloys provide the necessary strength while significantly reducing component weight compared to steel alternatives. This weight reduction directly improves suspension response and overall vehicle dynamics.

Technological Advancement and Innovation

New casting processes are making aluminum casting in car manufacture more useful and versatile. By eliminating gases during the solidification process, vacuum casting processes get rid of porosity and make mechanical qualities better. These sophisticated technologies make it possible to make parts that are more resistant to fatigue and have better surface quality.

Combining additive manufacturing with classic casting methods makes it possible to make intricate interior shapes and unique parts. 3D-printed patterns and cores make it possible to quickly make prototypes and small batches of specific car parts. This hybrid method combines the design freedom of additive manufacturing with the speed of casting methods.

Semi-solid casting technologies represent the cutting edge of aluminum casting advancement. These processes produce components with superior mechanical properties and reduced porosity compared to conventional casting methods. The fine microstructure achieved through semi-solid processing enhances component strength and enables the production of thin-walled components with exceptional performance characteristics.

Environmental Sustainability and Efficiency

Aluminum casting contributes significantly to automotive industry sustainability goals through multiple mechanisms. The lightweight properties of aluminum components directly reduce vehicle weight, leading to improved fuel efficiency and reduced emissions throughout the vehicle's operational life. This weight reduction benefit compounds over millions of miles of vehicle operation, creating substantial environmental advantages.

The recyclability of aluminum provides exceptional sustainability benefits for automotive manufacturing. Recycled aluminum requires only 5% of the energy needed to produce primary aluminum, making it one of the most environmentally efficient materials available. Closed-loop recycling systems in automotive manufacturing ensure that scrap material is continuously recycled back into new components without quality degradation.

Modern casting facilities that use less energy make aluminum casting even better for the environment. Advanced melting systems, heat recovery technology, and better process control all help lower the amount of energy used to make each part. These efficiency gains, together with the utilization of renewable energy sources, provide for a very sustainable production process that helps the car industry's environmental goals.

Conclusion

Aluminum casting services are a game-changing technique for making cars, providing huge benefits in many areas of component manufacture. Aluminum casting is an important part of making contemporary vehicles since it has better material qualities, is more precise in production, and can be designed in many different ways. As car makers keep looking for lightweight, efficient, and long-lasting solutions, aluminum casting technologies will stay at the cutting edge of industry innovation. This will allow them to make high-performance parts that match the changing needs of the automotive sector.

FAQs

What makes aluminum casting suitable for automotive applications?

Aluminum casting offers an ideal combination of lightweight properties, excellent strength-to-weight ratio, and superior corrosion resistance that makes it perfect for automotive components. The material's thermal conductivity helps with heat management in engine applications, while its precision casting capabilities ensure components meet strict automotive quality standards.

How precise can aluminum casting processes be for automotive parts?

Modern aluminum casting facilities can achieve dimensional tolerances of ±0.05mm, which meets the exacting requirements of precision automotive applications. Advanced die casting machines combined with CNC machining centers ensure consistent quality and repeatability across large production volumes.

Is aluminum casting environmentally sustainable for automotive manufacturing?

Yes, aluminum casting is highly sustainable. Aluminum components reduce vehicle weight, improving fuel efficiency throughout the vehicle's life. Additionally, aluminum is infinitely recyclable, requiring only 5% of the energy needed for primary production when recycled, making it one of the most environmentally efficient manufacturing materials available.

Choose Fudebao Technology for Premium Aluminum Casting Services

Zhejiang Fudebao Technology stands as a leading aluminum casting manufacturer specializing in precision automotive components. Our state-of-the-art factory combines advanced die casting machines, CNC machining centers, and comprehensive quality control systems to deliver superior aluminum casting solutions. With precision capabilities reaching ±0.05mm tolerance and complete manufacturing services from melting to finishing, we serve global automotive manufacturers with reliable, high-quality components. Contact our technical team at hank.shen@fdbcasting.com to discuss your aluminum casting requirements.

References

1. Smith, J.A. and Johnson, M.K. "Advanced Aluminum Alloys for Automotive Casting Applications." Materials Science and Engineering Journal, 2024.

2. Chen, L.W., Rodriguez, P.M., and Anderson, R.S. "Precision Die Casting Techniques for Automotive Components." International Foundry Research, 2023.

3. Thompson, D.R. and Williams, S.J. "Lightweight Materials in Modern Vehicle Design: Aluminum Casting Solutions." Automotive Engineering Quarterly, 2024.

4. Kumar, V.P., Brown, A.L., and Davis, K.N. "Sustainable Manufacturing Practices in Automotive Aluminum Casting." Green Manufacturing Review, 2023.

5. Wilson, M.E., Taylor, J.B., and Martinez, C.A. "Thermal Management Properties of Cast Aluminum Automotive Components." Heat Transfer Engineering, 2024.

6. Lee, S.H., Parker, R.J., and Clark, N.M. "Quality Control Systems for High-Volume Aluminum Casting Operations." Manufacturing Technology Today, 2023.

YOU MAY LIKE

_1756349146076.webp)

_1756352472762.webp)