Understanding Porosity in Aluminum Die Castings

Definition and Types of Porosity

Porosity in aluminum die castings refers to the presence of voids or cavities within the metal structure. These defects can significantly impact the mechanical properties and overall performance of the cast components. There are two main types of porosity:

- Gas porosity: Caused by trapped gases during the casting process

- Shrinkage porosity: Occurs due to metal contraction during solidification

Understanding these types is crucial for implementing effective measurement and control strategies. Gas porosity often appears as spherical voids, while shrinkage porosity typically has an irregular, branching structure.

Causes of Porosity in Die Castings

Several factors contribute to porosity formation in aluminum die castings:

- Inadequate venting of the die cavity

- Improper gating and runner system design

- Incorrect metal temperature or injection speed

- Contamination of the molten metal

- Insufficient application of die lubricants

By identifying and addressing these causes, manufacturers can minimize porosity and improve casting quality. Regular monitoring and analysis of porosity levels help in fine-tuning the casting process for optimal results.

Impact of Porosity on Cast Component Performance

Porosity can significantly affect the performance and reliability of aluminum die cast components:

- Reduced mechanical strength and ductility

- Increased risk of fatigue failure

- Compromised pressure tightness in hydraulic or pneumatic applications

- Degraded surface finish and aesthetic quality

- Potential for corrosion initiation sites

Accurate measurement and control of porosity are essential for ensuring that cast components meet the required specifications and perform reliably in their intended applications.

Standard Methods for Measuring Porosity in Aluminum Die Castings

Archimedes Principle Method

The Archimedes Principle method is a widely used technique for measuring the overall porosity of aluminum die castings. This method involves:

- Weighing the sample in air

- Weighing the sample when submerged in a liquid (usually water)

- Calculating the porosity based on the difference in weights and the known density of the material

While simple and cost-effective, this method provides an average porosity value for the entire sample and doesn't offer information about the distribution or size of individual pores. It's particularly useful for quality control and process monitoring in production environments.

Metallographic Analysis

Metallographic analysis involves examining polished cross-sections of the casting under a microscope. This method provides detailed information about:

- Pore size and shape

- Distribution of porosity within the sample

- Distinction between gas and shrinkage porosity

Radiographic Testing

Radiographic testing uses X-rays or gamma rays to create images of the internal structure of die castings. This non-destructive method can reveal:

- Internal voids and defects

- Porosity distribution throughout the casting

- Large-scale structural issues

Radiographic testing is particularly useful for inspecting complex geometries and thick sections where other methods might be less effective. However, it requires specialized equipment and trained personnel to interpret the results accurately. Digital radiography has made this method more accessible and efficient for many manufacturers.

Advanced Techniques for Porosity Measurement in Aluminum Die Castings

Computed Tomography (CT) Scanning

Computed Tomography (CT) scanning represents a significant advancement in porosity measurement for aluminum die castings. This technique offers:

- 3D visualization of the entire casting's internal structure

- Precise quantification of pore size, shape, and distribution

- Non-destructive analysis of complex geometries

- Ability to detect both surface and internal defects

CT scanning provides unparalleled detail and accuracy in porosity measurement. It allows manufacturers to analyze the relationship between porosity and casting parameters, leading to improved process control and product quality. While the equipment is expensive, the insights gained can justify the investment for high-value or critical components.

Ultrasonic Testing

Ultrasonic testing is another non-destructive method for detecting and measuring porosity in aluminum die castings. This technique involves:

- Sending high-frequency sound waves through the casting

- Analyzing the reflected waves to detect discontinuities

- Interpreting the results to identify and characterize porosity

Ultrasonic testing is particularly effective for detecting sub-surface defects and can be automated for high-volume production. It's sensitive enough to detect small pores and can provide information about their size and location. However, complex geometries and surface conditions can sometimes pose challenges for this method.

Helium Leak Testing

Helium leak testing is a specialized method used primarily for detecting through-porosity in pressure-tight components. The process typically involves:

- Sealing the component and evacuating the air

- Exposing the exterior to helium gas

- Using a mass spectrometer to detect any helium that penetrates through pores

This method is highly sensitive and can detect extremely small leaks, making it valuable for applications where pressure-tightness is critical. While it doesn't provide information about internal porosity that doesn't connect to the surface, it's an excellent complementary technique to other porosity measurement methods.

Conclusion

Effective measurement of porosity in aluminum die castings is crucial for maintaining product quality and optimizing manufacturing processes. From traditional methods like the Archimedes Principle to advanced techniques such as CT scanning, manufacturers have a range of tools at their disposal. The choice of method depends on factors like the required level of detail, production volume, and specific quality control needs. By implementing appropriate standards and methods for porosity measurement, die casting manufacturers can ensure the production of high-quality, reliable components that meet or exceed industry standards.

FAQs

1. What is the most accurate method for measuring porosity in aluminum die castings?

Computed Tomography (CT) scanning is generally considered the most accurate method, providing detailed 3D visualization of porosity throughout the casting.

2. How does porosity affect the strength of aluminum die castings?

Porosity can significantly reduce the mechanical strength and ductility of castings, potentially leading to premature failure under stress.

3. Can porosity in aluminum die castings be completely eliminated?

While it's challenging to eliminate porosity entirely, proper process control and advanced casting techniques can minimize it to acceptable levels for most applications.

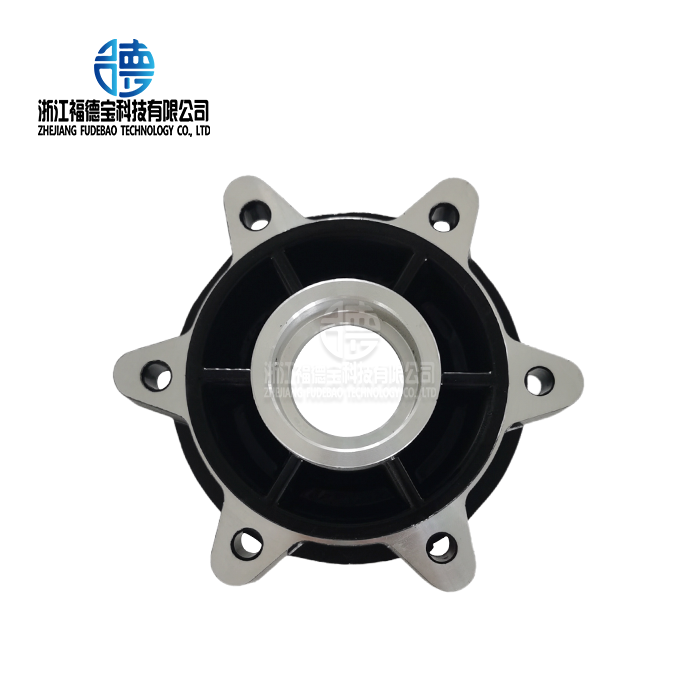

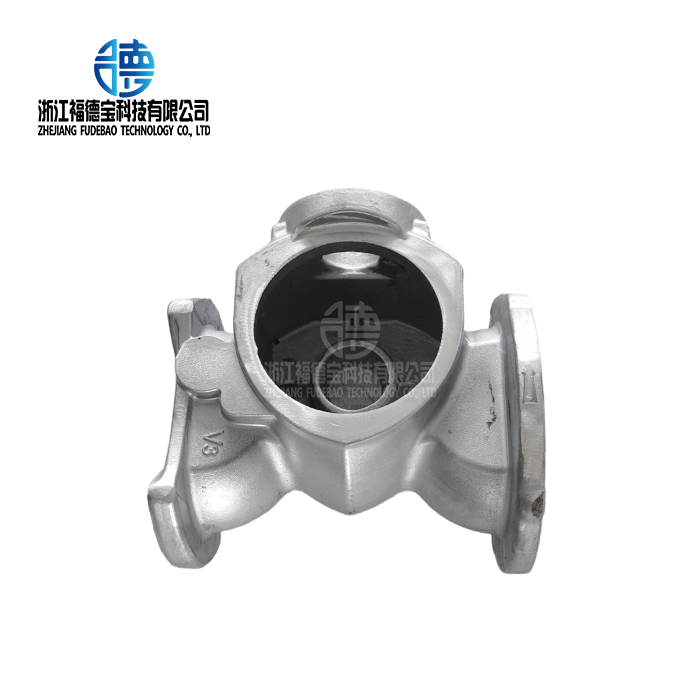

Professional Aluminum Die Casting Services | Fudebao Technology

At Fudebao Technology, we are a trusted aluminum die casting manufacturer providing custom aluminum die casting services for automotive, industrial, and aerospace sectors. With advanced equipment and over a decade of precision casting expertise, our die casting foundry ensures exceptional dimensional accuracy, superior surface finish, and minimized porosity. As a reliable custom aluminum casting supplier, we deliver end-to-end solutions - from mold design and production to finishing and inspection - to meet the most demanding OEM standards. For high-quality aluminum die casting components backed by engineering excellence and consistent performance, Contact us at hank.shen@fdbcasting.com.

References

1. Smith, J. D. (2018). "Advanced Techniques in Aluminum Die Casting Porosity Measurement." Journal of Materials Engineering and Performance, 27(5), 2145-2158.

2. Johnson, A. R., & Brown, L. K. (2019). "Comparative Analysis of Porosity Measurement Methods for High-Pressure Die Castings." International Journal of Metalcasting, 13(4), 867-880.

3. Thompson, R. C. (2020). "The Impact of Porosity on Mechanical Properties of Aluminum Alloy Die Castings." Materials Science and Engineering: A, 782, 139267.

4. Garcia-Hinojosa, J. A., et al. (2021). "Application of Computed Tomography in Porosity Assessment of Aluminum Die Castings." NDT & E International, 102, 102289.

5. Lee, S. G., & Gokhale, A. M. (2017). "Quantitative Characterization of Porosity in Die-Cast Aluminum Alloy A380." AFS Transactions, 125, 497-504.

6. Chen, X., & Liu, Y. (2019). "Advances in Non-Destructive Testing Methods for Porosity Evaluation in Aluminum Die Castings." Materials Evaluation, 77(12), 1452-1465.

_1756348543350.webp)

_1756350092126.webp)

_1756352340434.webp)